Rigging Hardware Explained: The Key to Reliable Tension and Stability

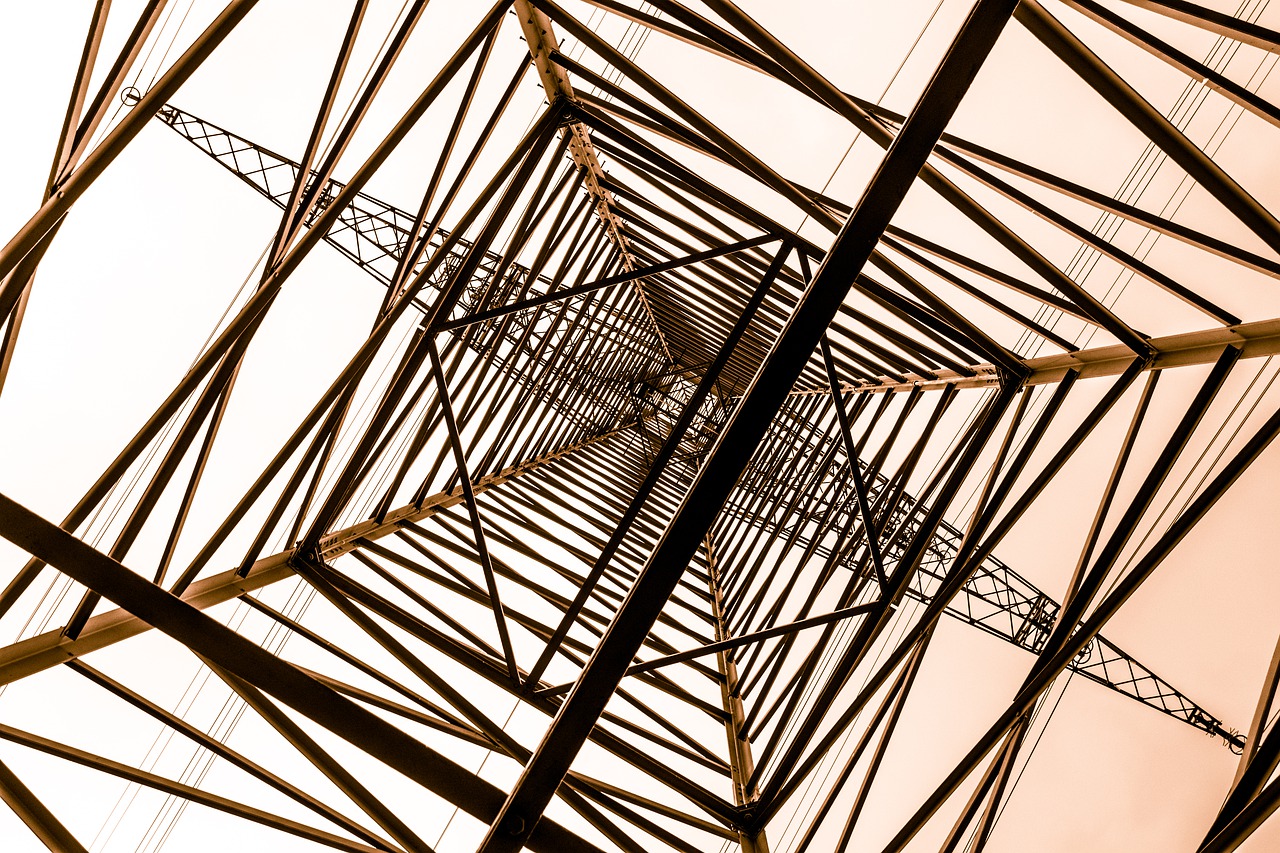

Just one, single loose shackle can transform a stable setup into a dangerous one. Scaffolding can begin to sway in the wind, buckle under its own weight or shift due to poorly secured rigging. These failures are rare, not because the structure itself is weak, but rather that the rigging solutions holding it all together have been overlooked. Components like turnbuckles, eye bolts, tensioners, shackles and wire rope clips may seem inconsequential in the vastness of a project, but they are the key to maintaining safe working practices.

Proper selection, installation and maintenance of rigging hardware are some of the fundamentals of ensuring safety, efficiency and long-term reliability. By treating rigging equipment as a critical part of the overall system rather than an afterthought, operators can prevent accidents, reduce downtime and keep every load secure and stable.

Rigging hardware is the unseen backbone of countless operations, industries and applications. This could be anything from construction sites and marine environments to manufacturing plants and entertainment rigs. When not correctly handled, crucial tension is lost, load/structural movement increases and the entire system becomes vulnerable to failure. That’s why understanding the function and limitations of each component is a minimum requirement prior to starting work.

What is Rigging Hardware?

The term ‘rigging hardware’ refers to the range of specialised tools and components that are used to maintain and manage tension, support loads and securely connect equipment and structures. Common examples are crucial in creating structural links for lifting devices and anchor points, or to secure and move varying levels of load.

Rigging hardware is one of those sections of components that are crucial across a wide range of industries, and it is vital to select high-quality turnbuckles and rigging tools for your projects.

The marine industry uses them to support masts and anchors or to reliably secure moving cargo under harsh conditions. In construction, they stabilise hoists, scaffolding units and other temporary structures. Rigging hardware is also used frequently in different industrial lifting operations to ensure that all loads are transferred safely. Home DIY projects can also make great use of these components when hanging heavy fixtures, for example.

Key Types of Rigging Hardware

Each type of rigging hardware has a distinct function that it performs to tension and create secure connections. If correctly chosen, installed and maintained, they can be a huge benefit to the safety of your worksite.

Turnbuckles are used to adjust tension and prevent slack in ropes, chains or cables. They are ideal for applications that require more precise adjustments.

Rigging screws do provide a similar service to turnbuckles but are built for more heavy-duty tensioning, like in industrial areas, marine applications and various structures. When dealing with heavy loads in harsh environments, rigging screws are the robust component for you.

Eye bolts and anchors provide secure and fixed points for cables, wiring and any other hardware, whereas shackles and hooks are essential for connecting different rigging elements safely. These components allow for reliable and flexible attachment points between lifting devices, ropes, chains and anything in between.

The choices don’t stop there; you now need to tackle the variety of material choices that will affect durability and overall performance. Stainless steel offers excellent corrosion resistance, making it ideal for marine or outdoor environments, while galvanised steel provides strong, cost-effective protection against rust and is suitable for construction and general industrial use.

How to Choose the Right Rigging Hardware

Choosing the right rigging hardware for your project is important for general safety and damage prevention and should start with understanding your initial load capacity. No matter how much care you take installing this hardware, if it’s not strong enough for the job, it will cause problems. You should always be comparing working load limits (WLL) against the weight and forces the components will encounter. WLLs are ‘safe operating figures’ and will actually be under their true maximum capacity for another layer of safety.

The type of application also matters; precision adjustments may just need turnbuckles, while heavy lifting might demand rigging screws or robust shackles. Always choose certified hardware from reputable and well-reviewed manufacturers and follow their installation and maintenance guidelines to ensure reliability. You will then need to consider potential environmental factors such as exposure to moisture, chemicals or extreme temperatures, which may require corrosion-resistant materials like stainless or galvanised steel.

By investing in high-quality rigging hardware, performing regular inspections and adhering to best practices will improve the longevity of your equipment and protect people and property. Proper selection, installation and maintenance of rigging hardware is essential for achieving reliable tension, stability and overall safety in every project.

Bitcoin

Bitcoin  Ethereum

Ethereum  Tether

Tether  XRP

XRP  USDC

USDC  TRON

TRON  Lido Staked Ether

Lido Staked Ether  Cardano

Cardano  Avalanche

Avalanche  Toncoin

Toncoin  Wrapped SOL

Wrapped SOL